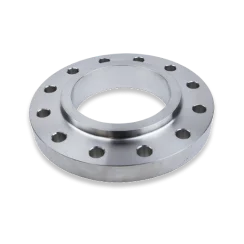

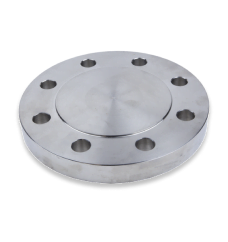

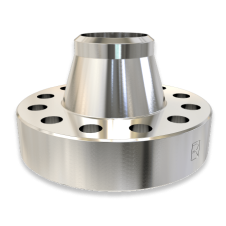

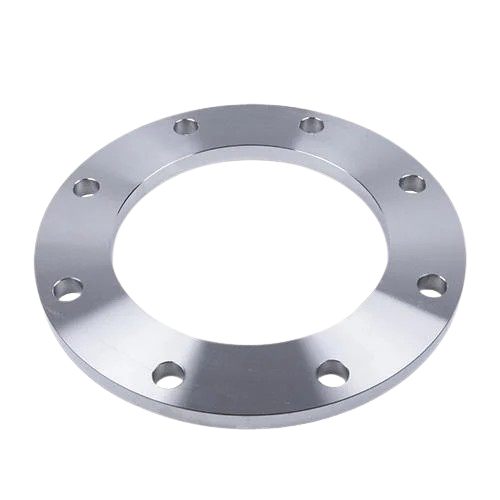

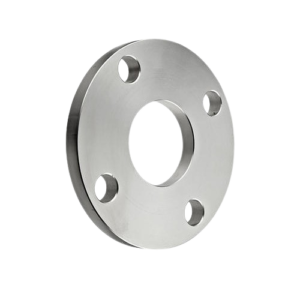

GI Flange

GI Flange

GI flanges are widely used in piping systems for their durability and resistance to corrosion. Made from mild steel coated with a layer of zinc, these flanges offer protection against rust and degradation, making them suitable for various applications, including water supply, drainage, and HVAC systems. The galvanization process enhances the lifespan of the flanges, allowing them to perform effectively in both indoor and outdoor environments.

The design of GI flanges typically follows standard specifications, such as those outlined by IS, ASTM, or EN standards. They are available in various sizes and pressure ratings, which makes them versatile for different piping configurations. Additionally, GI flanges are easy to install and maintain, contributing to their popularity in construction and industrial projects. Their lightweight nature also simplifies handling and reduces installation costs.

One of the key advantages of GI flanges is their cost-effectiveness, especially when compared to stainless steel or alloy flanges. While they provide good strength and functionality, their lower price point makes them an attractive choice for budget-conscious projects. Overall, GI flanges are a practical solution for many piping applications, balancing performance, longevity, and affordability.

Requirement Direct Call Us On

Grades

- IS 2062

- ASTM A36

- ASTM A105

- EN 10025 S235

- ASTM A515

Features

- Corrosion Resistance

- Cost-Effective

- Durability

- Lightweight

- Good Weldability

- Versatile Applications

- Standardized Dimensions

Advantages

- Corrosion Resistance

- Cost-Effective

- Lightweight

- Good Strength

- Easy to Install

- Low Maintenance

- Versatile Applications

Materials of Construction

- Galvanized Iron

- Mild Steel

- Carbon Steel