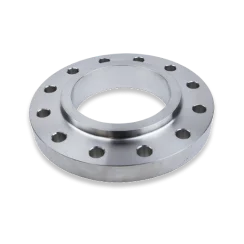

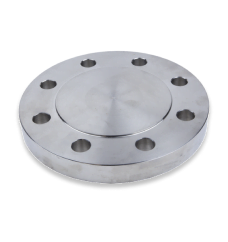

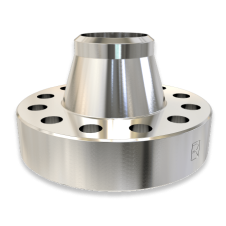

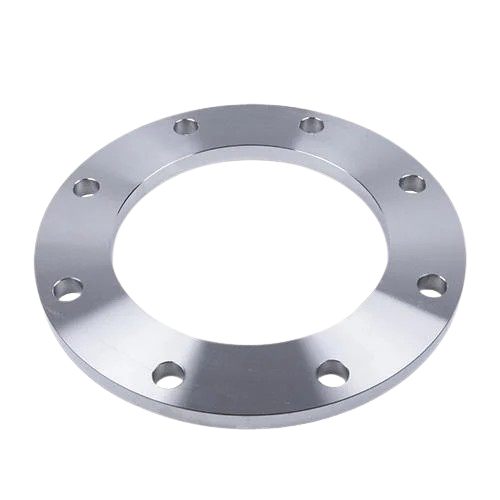

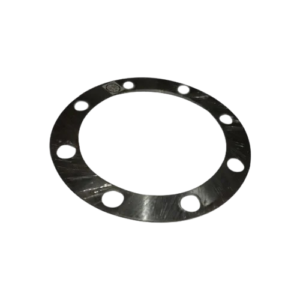

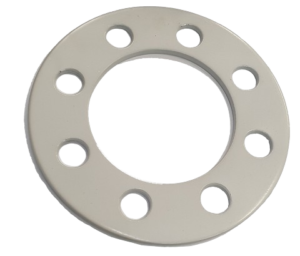

Rim Plate

Rim Plate

A rim plate, often referred to as a flange rim or rimmed plate, is a structural component used primarily in bolted connections within piping systems and machinery. This circular plate features a raised edge that provides a robust surface for securing bolts, ensuring a stable connection between various components. Rim plates are commonly utilized in applications where enhanced sealing and load distribution are required, such as in tanks, vessels, and industrial piping systems.

One of the key benefits of rim plates is their ability to improve the structural integrity of joints. By distributing loads evenly across the surface, they help minimize the risk of stress concentrations that can lead to failures or leaks. Rim plates can be made from a variety of materials, including carbon steel, stainless steel, and alloys, allowing them to be tailored to specific operational conditions and environmental factors. This adaptability makes them suitable for both high-pressure and corrosive environments.

Installation of rim plates is generally straightforward, requiring proper alignment and fastening to ensure a secure connection. They can be used in conjunction with gaskets to enhance sealing capabilities, making them an effective choice for preventing leaks in critical systems. Overall, rim plates play a vital role in maintaining the reliability and performance of piping and mechanical assemblies, contributing to the overall safety and efficiency of industrial operations.

Requirement Direct Call Us On

Grades

- A36

- A105

- A516

- 304

- 316

- F11

- F22

- S235

- S355

Features

- Raised Edge Design

- Robust Load Distribution

- Enhanced Sealing Capability

- Variety of Materials

- Standardized Dimensions

- Corrosion Resistance Options

- Ease of Installation

- Compatibility with Gaskets

- Durability in Harsh Environments

Advantages

- Enhanced Structural Integrity

- Improved Load Distribution

- Effective Sealing

- Durability

- Corrosion Resistance Options

- Ease of Installation

- Compatibility with Various Gaskets

- Cost-Effective Solution

- Versatile Applications

Materials of Construction

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Cast Iron

- Aluminum

- Plastic

- Copper