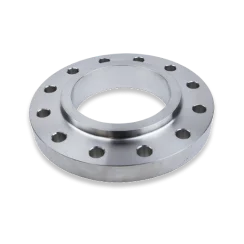

Weld Neck Flange

Weld Neck Flange

Weld neck flanges are a type of flange that features a long tapered neck, designed to be welded to the end of a pipe. This design provides a strong, robust connection, making weld neck flanges ideal for high-pressure and high-temperature applications. The taper of the flange neck helps to distribute stress more evenly, reducing the likelihood of failures at the weld joint. Because of their strength and reliability, weld neck flanges are commonly used in critical applications in industries such as oil and gas, chemical processing, and power generation.

One of the key advantages of weld neck flanges is their ability to accommodate changes in temperature and pressure without compromising the integrity of the connection. The design allows for a smooth transition between the flange and the pipe, minimizing turbulence and potential erosion in the system. This feature is particularly beneficial in applications where flow efficiency is crucial. Additionally, weld neck flanges can be manufactured in various materials, including carbon steel, stainless steel, and alloy steel, making them suitable for a wide range of corrosive and non-corrosive environments.

Installation of weld neck flanges requires careful alignment and skilled welding, which can increase installation time and labor costs compared to other flange types. However, the long-term benefits, such as reduced maintenance and increased reliability, often outweigh these initial costs. Overall, weld neck flanges are a trusted choice for many demanding applications, providing a secure and durable connection that enhances the overall performance of piping systems.

Requirement Direct Call Us On

Grades

- F304

- 304L

- 304H

- 316

- 316L

- 316Ti

- 310

- 310S

- 321

- 321H

- 317

- 347

- 347H

- 904L

- Duplex stainless steel UNS S31803

- 2205

- Super Duplex stainless steel UNS S32750

Features

- Tapered Neck Design

- Strong Weld Connection

- Pressure and Temperature Resistance

- Smooth Flow Transition

- Variety of Materials

- Standardized Sizes and Ratings

- Versatile Applications

- Reduced Stress Concentration

- Suitable for High-Pressure Systems

Advantages

- Strong Connection

- High Pressure and Temperature Tolerance

- Reduced Stress Concentration

- Smooth Flow Path

- Versatile Material Compatibility

- Long Service Life

- Ease of Maintenance

- Customizable Design

- Reliable for Critical Applications

Materials of Construction

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Nickel Alloys

- Titanium

- Brass